plate 1 (below) |

In Ayrshire

Notes 16, the present author describes two rival gas works

operating in Newmilns and fighting it out in great contention. The

burgh was a source of amusement for the people of the neighbouring

villages through its claim to have two of everything, signifying

its public utilities and civic institutions. However in this case

the correct number vaunted was three. The two establishments mentioned

in the earlier article produced coal gas, but just off Main Street

a small factory also known as the 'gas works' was in business.

The Mercury Gas Company resembled in entrepreneurial flair many

small firms in Ayrshire towns that were trading successfully in

national and international markets. In time many were gobbled up

by predators or had their product replaced by modern equivalents

or new sources of energy, but the Mercury had a healthy existence

during the first decades of the twentieth century under the ownership

and direction of John MacPherson. First described as a plumber he

later, when he had established his company, transmogrified himself

into a gas engineer. Both designations were appropriate when it

came to buying in the cylinders and machined parts for the apparatus

and linking them with the necessary mechanism and pipes.

The plant provided heating and lighting to premises in isolated

localities, such as farms and country houses, not attached to the

main gas supplies, or to customers who chose to be independent of

the town gas companies. It was suitable for schools (such as the

Grammar School, Pocklington, East Riding of Yorkshire), reading

rooms (such as Drymen, Stirlingshire) and small businesses, such

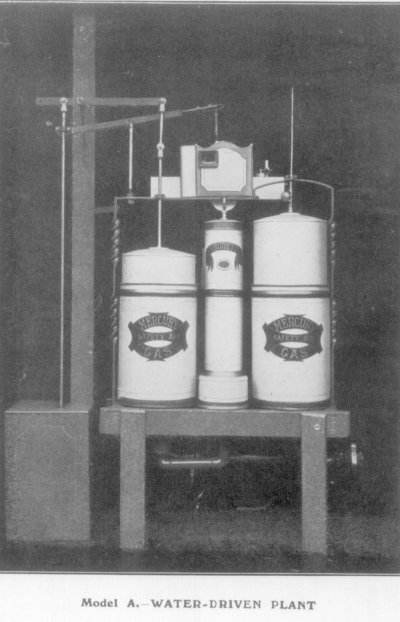

as the Premier Tanneries in Glengarnock. Plate 1 shows the more

popular model of water-driven plant that could be adapted to supply

households and premises with the required number of lights or heating

apparatus. A 150 light plant was installed at Drumshoreland Hospital,

near Broxburn, West Lothian. The architect of the hospital approved

it for its 'special feature of conveying its own air in the pipes,

thereby saving the air in the rooms from being robbed of oxygen

which is so essential for sick rooms. [It] is quite a triumph from

a health point of view, and should commend itself to all public

and private institutions where a pure atmosphere is valued.' (note

1)

The system had clear economic advantages over coal gas, which cost

around 3s 6d (171/2p) per 1000 cubic feet. At the same period the

Mercury was run on a mixture of air and petrol, 971/2% air to 21/2%

petrol, operated by a small water engine with a pressure of 20 lbs.

In one test, using a quarter of a gallon of petrol, costing at that

time about 1s (5p) a gallon, '219 cubic feet of air gas were made

and consumed through ten burners throughout the house, using 36

gallons of water costing 0.216 pence, less than a farthing.' (note

2) Advantages of the system were the elimination of condensation

and, as a safety gas, it eradicated all chance of asphyxiation or

explosion in any apartments where the gas burned. No unpleasant

odours were produced and, as an automatic plant, it turned itself

on when one light was ignited and stopped working when the last

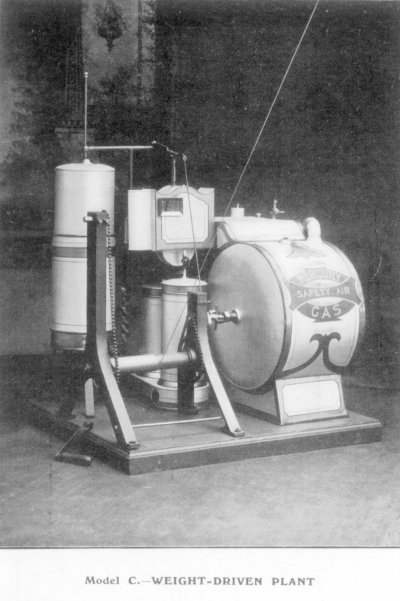

light was extinguished. If circumstances prevented the use of water

or it was not available the plant could be operated by weight and

pulley as shown in Plate 2.

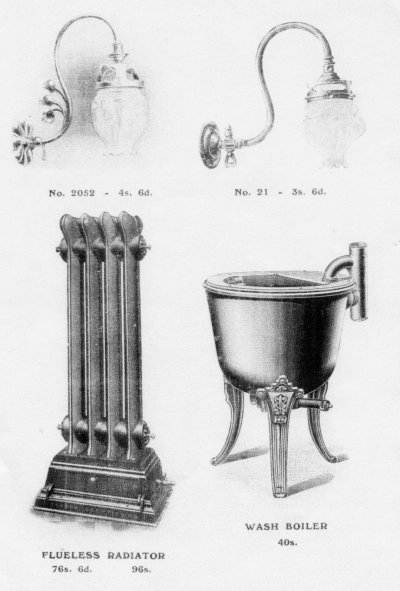

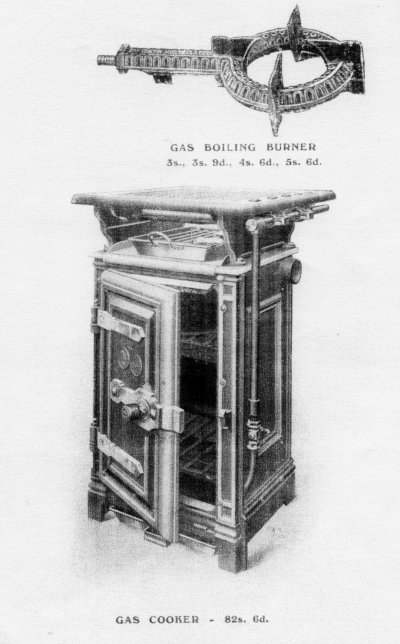

All the standard equipment necessary for lighting, heating and cooking

could be operated from the installation: lights, radiators, boilers,

cookers, irons, gas fires and even ironing machines, which were

given a favourable report by Mr Watson of the Loudoun Laundry Co.

Another satisfied customer further afield, but in the same line

of work was the D & J Tullis Laundry in South Africa. Some of

the wide range of products offered by the company are shown in Figures

1 and 2, but every type of domestic and industrial appliance used

in the coal gas industry could also be used in the Mercury system

The widespread and international utilisation of the Company's plant

is indicated by the addresses of a selection of its clients:-

Oil Well Engineering Co., Cheadle, Manchester

Burmah Oil Co., Burmah

Hall, Leslie & Co., Buenos Aires, Argentina

Mr Buchanan, Tobago

Mr Harry Moore, 8-10 Petit Dock, Ghent, Belgium

Fumigalli & Co., heating engineers, Genova, Italy

M. Ruffenacht, Rue de Versailles, Paris

Cuckney Church, Nottinghamshire

After quick growth following the launch of the business with prospects

of further improvement, the company settled down into a regular

steady trade. It displayed its various models and techniques at

many industrial exhibitions winning awards, including the prestigious

gold medal at Manchester in 1910. An office with a showroom was

opened in Bath Street, Glasgow, moving later to West Regent Street,

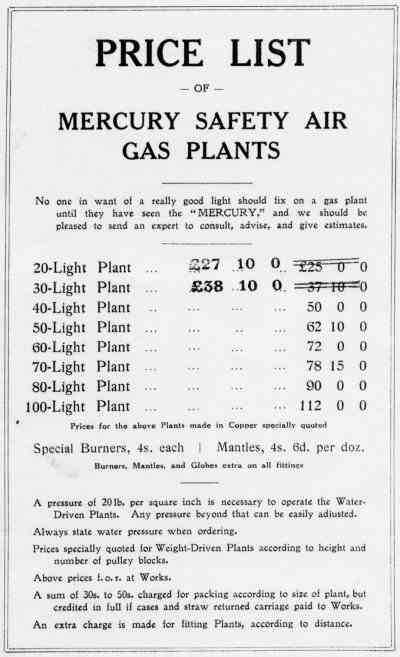

while the works remained throughout in Newmilns. An undated price-list

of the company's products is shown in Figure 3, and it maintained

a stake in the market until the outbreak of the Second World War.

The company, regardless of the appeal of its product and its competitive

edge, could not hope to survive without an enlarged sales force

and an increased works capacity. Branch factories in areas most

suited for commercial development might have nourished further growth,

but alternative systems of motive power and lighting in rapidly

expanding coal gas and electricity enterprises contributed to the

company's stagnation. The cleanliness, efficiency and safety of

the company's gas plant might have maintained a niche in the market,

but the pre-war development of bottled gas, including Calor Gas,

endangered the Mercury's on-site mechanical system. Without access

to the company records, the ebb and flow of its business activity

cannot be traced. It remained a family concern with limited prospects

for expansion even with its widespread commercial outlets.

Many small businesses, unless they acquired government orders, suffered

eclipse during the Second World War. The Mercury Safety Air Gas

Co was already in decline and the last references to its existence

lie in the valuation rolls for the Burgh of Newmilns & Greenholm

for 1940. What was described as the company's premises at Main Street

from 1911 onwards as a workshop had by 1940 become merely a store.

By the end of the war it was recorded as vacant premises, which

soon after were cleared of all residual equipment and materials

to be converted into the local fire brigade station.

At one time the 'gas works' had formed part of a small industrial

complex alongside Thomson's aerated water factory and Todd's stocking-making

workshop, all within a typical townscape of domestic housing, retail

shops, factories and workshops. Most people lived by or near their

place of work in small, self-sufficient communities. The trend towards

the much-acclaimed economies of scale in business endeavour soon

gave the coup de grace to most small forms as the move to larger

units accelerated. These were located at a distance, and the social

and economic structure of small towns and villages was weakened

or disintegrated. The Mercury Gas Company characterised the enterprise

and acumen of a period of industrial development unlikely ever to

be repeated.

Notes

1. William Baillie, architect, Glasgow, quoted in the business

brochure of the Mercury Safety Air Gas Co Ltd., p.14.

2. Brochure of Mercury Safety Air Gas Co Ltd., p.2.

© Jim Mair 2003

|